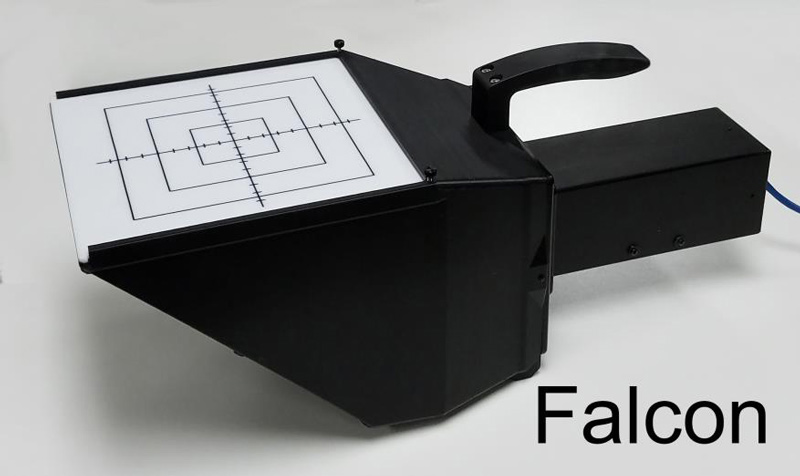

XRV-2000 Falcon Beam Profiler

The XRV-2000 Falcon Beam Profiler combines high-energy radiation detection with precision two-dimensional metrology to form a completely electronic alternative to film-based measurements. The XRV-2000 Falcon measures the XY location and profile of radiation beams with unmatched speed and accuracy. Single beams and proton energy layer patterns up to 19 × 19 cm in size may be directed at the scintillator surface from vertical and horizontal orientations for measurement. Automation scripts can be used to capture changes in the beam shape, intensity, and location over time.

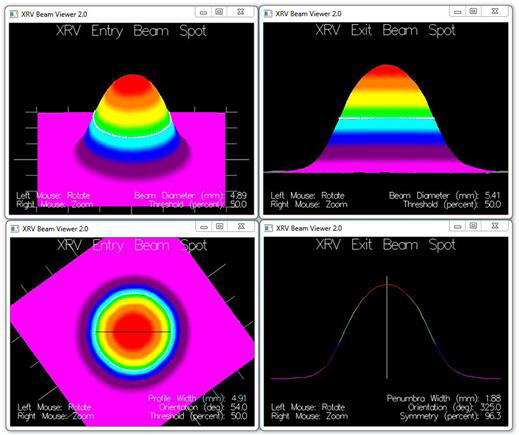

XRV systems calibrate proton and radiosurgery systems or industrial radiation sources that must deliver precise amounts of radiation to targeted regions in 3D space. The correct operation of pencil beam scanning or mechanical leaf collimators used in these systems can be quickly verified. Beam FWHM diameter measurements are accurate to ±0.1 mm and centroid positions to ±0.2 mm. Beam viewing software enables real-time any-angle viewing of the captured profile data with live penumbra and symmetry-style measurements. Captured images can be exported to ImageJ or other image analysis software.

All operations are controlled by a laptop or desktop PC supplied with the camera phantom. The XRV comes with a 30 meter (100 feet) USB3 power-over-fiber extender cable so that the system PC and operator can be located safely away from the radiation source. The digital camera phantom weighs approximately 3.5 kilograms (7.7 pounds) and is stored in the Pelican case provided as part of the system.

Features and Benefits:

- Proton and X-ray beam Quality Assurance

- Real-time 200 × 200 mm beam profile and position capture

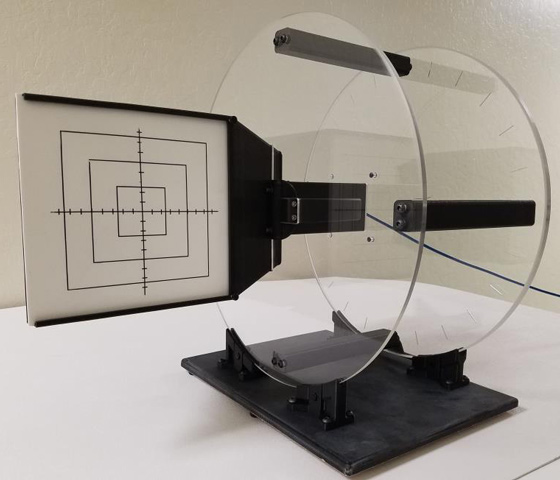

- 360 degree rotation with optional Gantry Cradle

- Effective Resolution 0.22 mm at 8 or 12-bits per pixel

- Flexible scintillator, fiducial, wedge, and build-up options

- BeamWorks Strata software includes GUI or script operation

- Individual or integrated frame capture modes

- Advanced beam profile viewing and measurements

- Statistical analysis macros for easy export to spreadsheets

- Proton range verification using optional LCW-200 or LCW-300

Operation

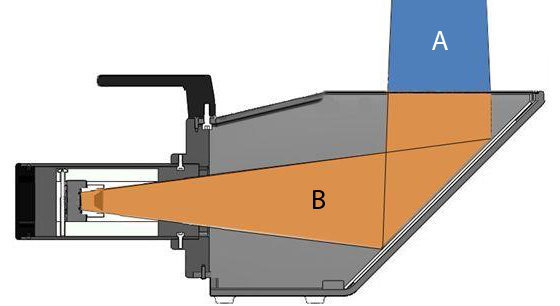

The XRV phantom may first be imaged with a CT scanner so that the fiducials can be used as a target for the treatment volume. Every beam of the test QA plan can then be measured for delivery accuracy. The XRV technology uses a scintillator to turn the invisible X-rays or protons into a spot of visible light that accurately represents the location and profile of the beam. A sensitive CCD camera then digitizes the beam spot and transfers the bitmap to the XRV computer for analysis and storage.

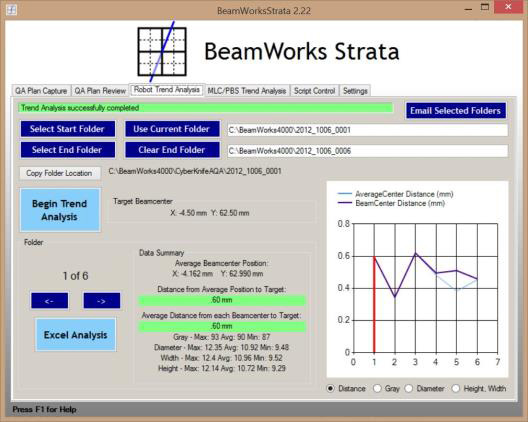

The BeamWorks Strata software is used to acquire, analyze, and archive XRV images. Beam data is displayed in 3D allowing real-time zoom and viewing angle selection. Beam height, width, penumbra and symmetry measurements are available from any angle of beam rotation. Spreadsheet macros are provided for extended statistical analysis of the captured data. Automated measurements can be made from the graphical user interface (GUI) or customized with an easy-to-use scripting environment.

The 200 × 200 mm scintillator turns the X-ray or proton beam (A) into a visible spot of light (B) that is reflected off the 45 degree mirror to the camera.

The XRV-2000 Falcon is shown below mounted in its Gantry Cradle, which enables 360-degree manual rotation. The axis of rotation is aligned with the scintillator for accurate beam measurements at all gantry angles.

BeamWorks Strata Target Trend Analysis

Specifications:

| XY Beam Center: | 0.2 mm |

|---|---|

| Repeatability: | ±0.04 mm (typical) |

| Beam Diameter: | 0.1 mm |

| Repeatability: | ±0.04 mm (typical) |

| Resolution: | 1280 × 960 pixels with 8 and 12-bits per pixel |

|---|---|

| Capture Rate: | 1 - 30 frames/sec (typical) |

| Scintillator Size: | 200 × 200 mm |

| Lens MTF: | Megapixel resolution |

| Camera Interface: | USB 3.0 |

| Camera top and sides: | 12.7 mm lead alloy or bismuth composite |

|---|---|

| CCD Lifetime: | ~1,500 beam hours |

| H × W × D: | 23 × 22 × 52 cm |

|---|---|

| Weight: | 3.5 kg (7.7 lbs) |

| Enclosure Material: | Aluminum and Plastic |

| Capture Trigger: | Auto, GUI, Script, or Network watch-file |

|---|

| Configurable to customer requirements |

| Electrical Power: | 110-220V or battery |

|---|---|

| Environment: | 5 to 30 degrees C; 90% humidity, no condensation; minimal vibration |

Notes:

- Contact us for higher camera resolutions.

- Contact us for custom shielding requirements. The camera may be replaced for a service fee after approximately 3 years as necessary.