XRV-124 3D Digital Camera Phantom

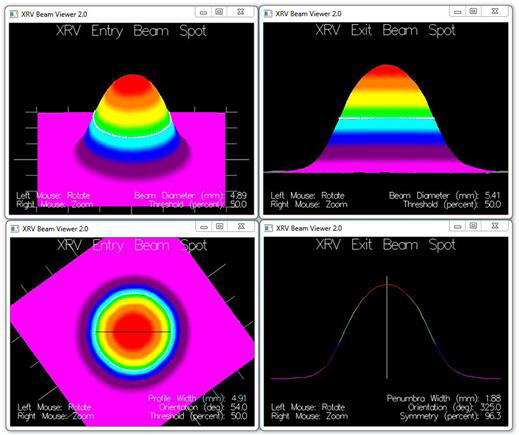

The XRV family of X-ray and proton beam inspection systems combine precision metrology with high-energy radiation detection to form a fully electronic alternative to film-based measurements. The XYZ location and vector of pencil-thin beams of ionizing radiation can now be measured with unmatched speed and accuracy. Beam vector, profile, and divergence can be obtained in seconds rather than hours. Automation scripts can be used to capture changes in the beam shape, intensity, location, and direction over time for use in later analysis or 3D volumetric reconstruction.

XRV systems verify that the proton and X-ray therapy subsystems (robot, collimator, radiation source, and kV imagers) are working together to accurately deliver radiation to the irregularly shaped lesion volume. Beam position measurements are accurate to 0.3 mm and measurement repeatability is typically 0.03 mm. Vector and beam viewing software enables real-time any-angle viewing of the captured data. Up to 4,000 frames of video can be captured real-time at rates from 1 to 30 frames per second.

All operations are controlled by a laptop or desktop PC supplied with the detector phantom. The XRV comes with a 30 meter (100 feet) power-over-fiber USB cable system so that the system PC and operator can be located safely away from the treatment room. The detector phantom weighs approximately 8 kilograms (17 pounds).

Features and Benefits:

- Real-time Proton and X-ray 3D beam vector and profile capture over 360 degrees of rotation

- 140 mm long field of view

- 4 – 60 mm beam/field widths

- Filmless Winston-Lutz delivery accuracy analysis

- Fast Star Shot pattern gantry wobble analysis

- MLC sliding window analysis

- Captures VMAT deliveries up to 10 minutes long in real-time

- VolumeWorks XL reconstructs 3D fluence volumes 10 × 10 × 15 cm

- Fixed and adjustable fiducial BBs for image guidance

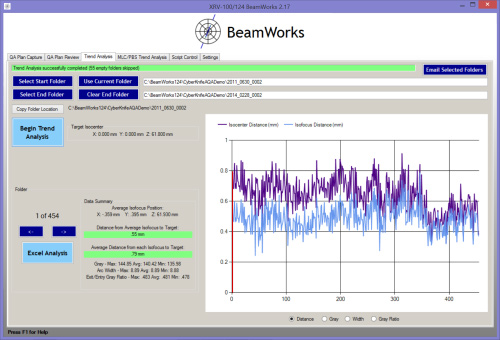

- BeamWorks software includes trend analysis and graphing of distance to plan, beam intensity, and dimensions

Operation

The XRV phantom is first imaged with a CT scanner so that the fiducials establish the treatment dose position during delivery. Every beam of the treatment plan can then be measured for delivery accuracy. The patented XRV technology works on the principle of the hodoscope: the X-ray or proton beam creates visible beam spots on the surface of the scintillator imaging cone at the front of the phantom. A sensitive CCD camera then digitizes the beam spots and transfers the bitmap to the XRV computer for computation into 3D vector and profile data.

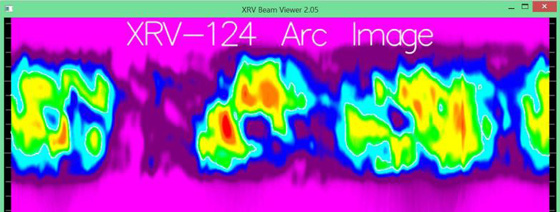

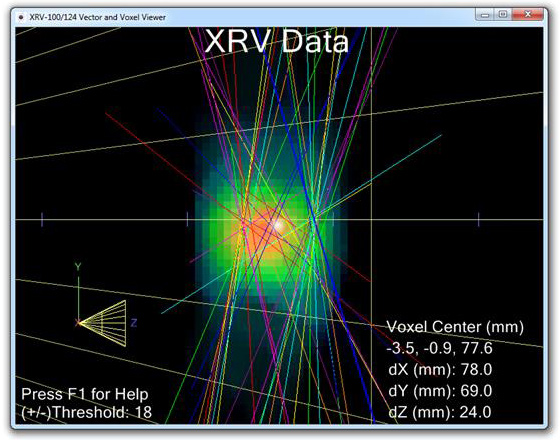

The BeamWorks and ArcWorks software is used to acquire, analyze, and archive XRV images. Beam vector and shape data are displayed in 3D using advanced GPU enabled algorithms. BeamWorks Delta allows two treatment plan captures to be compared beam-by-beam. VolumeWorks XL uses the captured vector and profile data to approximate the 3D treatment volume. Vectors and voxels are displayed together to represent volumes up to 10 × 10 × 15 cm.

Shown above is a dewarped Arc representation of a 360 degree small field VMAT delivery to the XRV-124 imaging cone.

3D Viewing of Beam Vectors and Fluence Voxels

BeamWorks Target Accuracy Trend Analysis

Specifications:

| XYZ Beam Center: | 0.3 mm (hi-res) |

|---|---|

| Repeatability: | ±0.03 mm (typical) |

| Vector Theta/Phi: | 0.3 degree (hi-res) |

| Repeatability: | ±0.1 degree (typical) |

| Resolution: | 1280 × 960 pixels or 640 × 480 pixels |

|---|---|

| Capture Rate: | 1 - 30 frames/sec |

| Cone Angle: | 45 degrees |

| Usable Cone Area: | 140 mm over 360 deg. Width: 30 - 60 mm |

| Lens MTF: | Megapixel resolution |

| Camera Interface: | USB 3.0 |

| Camera top and sides: | 12.7 mm thick bismuth and polymer composite |

|---|---|

| CCD Lifetime: | ~1,500 X-ray beam hours |

| H × W × D: | 27 × 19 × 67 cm |

|---|---|

| Weight: | 7.8 kg (17.2 lbs) |

| Enclosure Material: | Aluminum and Plastic |

| Capture Trigger: | Auto, GUI, Script, or Network watch-file |

|---|

| Configurable to customer requirements |

| Electrical Power: | 110V, 2 or 4A |

|---|---|

| Environment: | 10 to 30 degrees C; 90% humidity, no condensation; minimal vibration |

Notes:

- Contact us for higher camera resolutions.

- Contact us for custom shielding requirements. The camera may be replaced for a service fee after approximately 3 years if necessary.